In an era where the use of fossil fuels has been proven to be harmful to the environment (and humans in general) alternative sources of energy and electricity are sought. One of the obvious sources is the wind to produce wind power.

Wind power means using the wind - harnessed by either a turbine, wind mill, wind pump or even sails (for ships) - to generate the desired amount of electricity to be used for home and commercial purposes. This provides an efficient power alternative that is clean, abundant and completely environmentally friendly.

Many countries have embarked on wind power ventures and have shown remarkable successes in generating power for their citizens. The drive now is to convince more people (and governments) to convert to wind power to meet their energy needs and demands. Once this has been achieved it is estimated that even more power can be generated than is currently being done making use of fossil fuels.

In the following sections the phenomenon of wind power will be investigated and some important conclusions will be reached.

What is Wind Power?

Wind power means that the wind is harnessed in one of a variety of ways to generate power or energy/electricity. This means that a natural resource is used to produce clean, environmentally friendly power. The most common ways of harnessing the power of the wind is using sails to propel ships and sail boats across the water. The most desirable way of using the wind to generate electricity is by erecting wind turbines.

Types of Wind Turbines

In order to understand how wind turbines work and how they manage to produce the amounts of energy that they do, one must understand the types of turbines that are currently in use.

There are two categories of wind turbines: the horizontal axis design (HAWT) and the vertical axis design (VAWT). These are based on the Darrieus egg-beater model. Since it is the more practical and popular, the HAWT enjoys more attention than its sibling, the VAWT.

The HAWT has its main rotorshaft at the top of the column along with the electrical generator. The turbines must be pointed into the wind and is positioned favourably by either a small weathervane or a wind sensor.

The rotor shaft and gearbox of the VAWT are positioned vertically and are also installed near the ground. This makes it more accessible for maintenance and other necessary adjustments. One of the reasons why this type of wind turbine is less popular is that it can produce what is known as pulsating torque.

Sizes of Wind Turbines

The size of a wind turbine is measured in kilowatt and they come in a variety of sizes. The smaller turbines are sized at smaller than 100 kilowatts and are often used in conjunction with other power generating equipment such as generators, batteries etc. These are described as hybrid systems.

The larger turbines range from 100 kilowatts to several megawatts and can be used either individually or in the form of wind farms - depending on the use of the turbine. When organized into wind farms, the wind turbines are capable of producing a mass of electricity for a specific electricity grid.

Of course there are massive turbines with huge capacities. The largest capacity wind turbine is the Enercon E-126 which delivers to a capacity of 7,58MW. Engineers and designers are currently also working on developing a turbine with a capacity of 10MW or more. These massive turbines promise to be the answer to the world's future energy demands and needs.

Wind Turbine Parts

In order to understand how these machines work, it is important to know what they consist of.

A standard wind turbine consists of sixteen main parts grouped into three main components:

A standard wind turbine consists of sixteen main parts grouped into three main components:

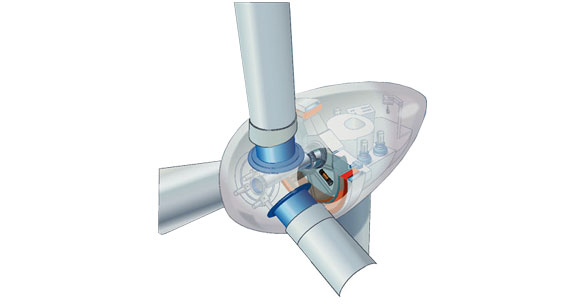

- The rotor component is the first of the components of the turbine and contributes approximately 20% of the total cost of the entire turbine.

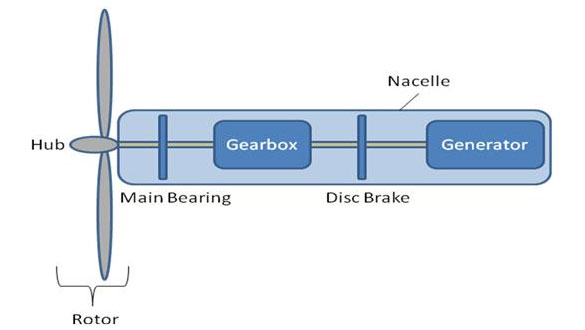

- The generator component contributes 34% of the total cost and consists of parts like the electrical generator and the gearbox.

- Contributing only 15% to the cost, the structural support component is the least expensive part of the entire turbine.

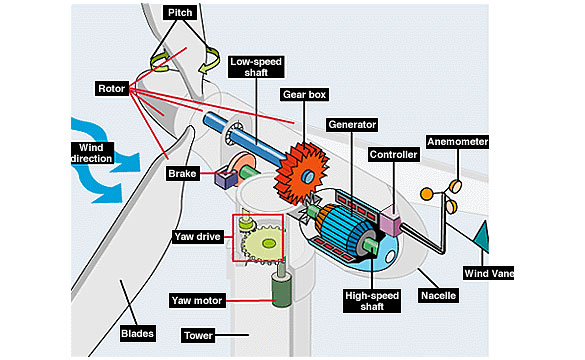

Making up these components, the following parts (in alphabetical order) are crucial to the proper functioning of the turbine:

- The anemometer is responsible for measuring the wind speed. It then transmits this information to the controller.

- Most turbines consist of blades. There are usually two or three blades that will start turning when the wind blows.

- In an emergency the turbine can be stopped by applying the brake. This can be done either mechanically, electrically or hydraulically.

- When the wind speed reaches 6 - 16 miles per hour (10 - 26km per hour) the controller starts the machine up. When the wind speed reaches 55 miles per hour (88 km per hour) the controller then shuts the machine off as winds speeds in excess of this speed may damage the blades.

- The gearbox works the same as the one found in a car - it is meant to control the rate at which the turbines accelerate.

- There is an off-the-shelf generator that is meant to provide the initial start-up electricity.

- The high speed shaft drives the generator, while the low speed shaft turns at 50 - 60 rotations per minute.

- On the top of the tower the nacelle houses the gearbox, the two shafts, the generator and controller as well as the brake.

- The pitch turns the blades out of the wind when necessary and in this way controls the speed of the blades.

- The rotor consists of the blades and the hub.

- The tower provides the height and support to the blades in order to catch the wind.

- Because it faces into the wind, this turbine is called the wind direction.

- Wind direction and speed is measured and communicated to the controller by the wind vane.

- The yaw drive ensures that the turbine continues to face into the wind.

- While the yaw drive controls the turbine, the yaw motor controls the yaw drive.

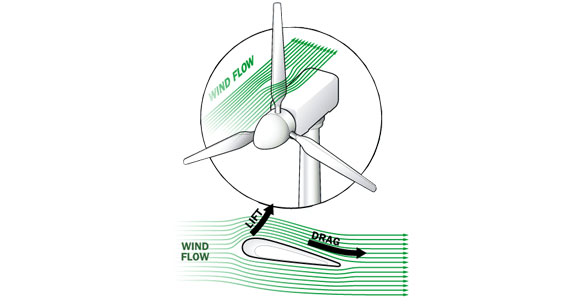

How does a Wind Turbine work?

To understand the working of the wind turbine, it is useful to take a quick look at its predecessors: windmills. Windmills worked by turning when the wind blows and, through various mechanisms attached to the blades, performs tasks like crushing corn or like conveying water into aqueducts etc.

The wind turbine takes this one step further. It can turn at different speeds and has a controller that will control when and how it works - to protect it from damage. It also has a gearbox that will regulate how fast the blades accelerate in order to make optimum use of both the machine and the wind.

As the wind turns the blades of the turbine they, in turn, turn the shafts running down the tower and are connected to a generator. The working of the shafts and the friction of the turning shafts link into the generator which then converts the energy created by the wind turbine into the useful electricity that is needed.

How to Build a Wind Turbine?

With all this information at hand, it is easy to believe that wind power is at your very fingertips. If only you could build a wind turbine. The good news is that it can be done quite easily from your home.

Some of the common materials that are needed are:

- A generator - It doesn't need to be a specific or specialised generator. It is good enough to get an off-the-shelf variety.

- Blades - these need to be durable to withstand the outdoor elements, as well as varying wind speeds. Generally PVC pipe is used for small wind turbines.

- A mounting that keeps it turned into the wind

- A tower to get it up into the wind

- Batteries and an electronic control system

The first step is to get all the material together. Work on each section individually and at the end put everything together. Make sure that you have a suitable generator or motor. Make the blades out of the PVC pipe and bolt them onto the hub. The hub is then attached to the generator using the mounting that the turbine will be standing on. Make sure that all the connections are sound and secure.

To make a base for the tower it is sufficient to use plywood or any other wood with the same qualities. Cut a disc of the desirable diameter that will support the tower, hub and blades. Mount the tower; attach the blades and hub, as well as the generator. Make sure that the shafts are in place and that the turbine can turn with the change of wind direction.

Then stand back and admire your handy work.

Wind Power Pros and Cons

There are several advantages to using wind power:

- Generating electricity using wind means that there is no toxic or radioactive waste being generated. There is also no pollution.

- Wind power can be harnessed by individuals as well as companies or governments. It produces as little or as much power needed.

- Wind is a renewable resource and therefore fossil fuels and resources are not being depleted.

There are also disadvantages to this kind of power:

- The turbines are sometimes considered unsightly - especially when there is a number of them.

- Wind turbines are also vulnerable to the elements and may be damaged by thunderstorms and lightning.

- The blades are not bird-friendly and they can end up hitting birds that are flying in that vicinity.

- Some turbines make a noise which increases when the wind speed is low. This can have an undesirable effect on the people in its immediate surrounds.

No matter what the pros and cons are, it is important to remember that the search for renewable energy is one of the main objectives of using wind power. It is entirely possible that the difficulties currently being experienced in using the wind turbines may be solved as time goes on and that this may prove to be one of the most desirable energy resourcesavailable to mankind.

Wind Turbine Efficiency

There has been some discussion about the efficiency of the wind turbine and debate about how much of the wind energy can be successful converted into electricity or power.

The formula that calculates this is:

Power in the wind = d (density of the wind) x D2 (turbine blade diameter)2 x V3 (velocity of wind)3 x C (a constant). This formula merely calculates the power in the wind - not the power available to us. The power available to us is a smaller percentage as not all the power in the wind can be harnessed and used.

Power in the wind = d (density of the wind) x D2 (turbine blade diameter)2 x V3 (velocity of wind)3 x C (a constant). This formula merely calculates the power in the wind - not the power available to us. The power available to us is a smaller percentage as not all the power in the wind can be harnessed and used.

The Betz law explains that some of the wind needs to move through the turbine blades in order to make room for the next amount of wind coming in. If 100% of the power would be harnessed, no more could be contained and converted. Betz scientifically calculated that only 59% of the power in the wind can be successfully captured and converted. This means that just over half of the power available to us is being converted and is available for use.

Wind Farms

Wind farms are large tracts of land that have been dedicated to the erection of wind turbines for the purpose of producing electricity. These farms consist of multiple wind turbines that provide power / electricity to a number of users.

The farm uses individual wind turbines and interconnects them with a medium voltage power collection system and a communications network. Further along the line, a substation increases the voltage with a transformer and is then connected with the higher voltage system.

In 1980 the world's first wind farm was started on the shoulder of Crotched Mountain. The 20 turbines used at this pioneering farm were rated at 30 kW. Today the largest wind farm in the world is the Roscoe Wind Farm in Texas, USA which produces 780 MW of energy.

Wind farms have become popular all over the world and are being seriously considered as alternatives to conventional power sources.

Wind Energy Finance

The National Renewable Energy Laboratory designed an online calculator, The Wind Energy Finance, to help developers and investors to help them make quick and detailed evaluations of the economic viability of potential utility-scale wind energy projects.

The calculator is user-friendly and only requires a few essential data inputs such as general assumptions, capital costs, operating expenses, financing, tax and economic assumptions as well as financial constraining assumptions.

The calculator takes the data and processes it and then produces the following outputs:

- Minimum energy payment to meet financial criteria

- The levelized cost of energy

- Potential payback period

- The net present value of the project

- Internal rate of return

- Summary and detailed cash flows.

Using this tool developers and investors have a quick, convenient future view of the wind farm project and both can evaluate the potential success of the project on reliable calculations and data.